Wheels

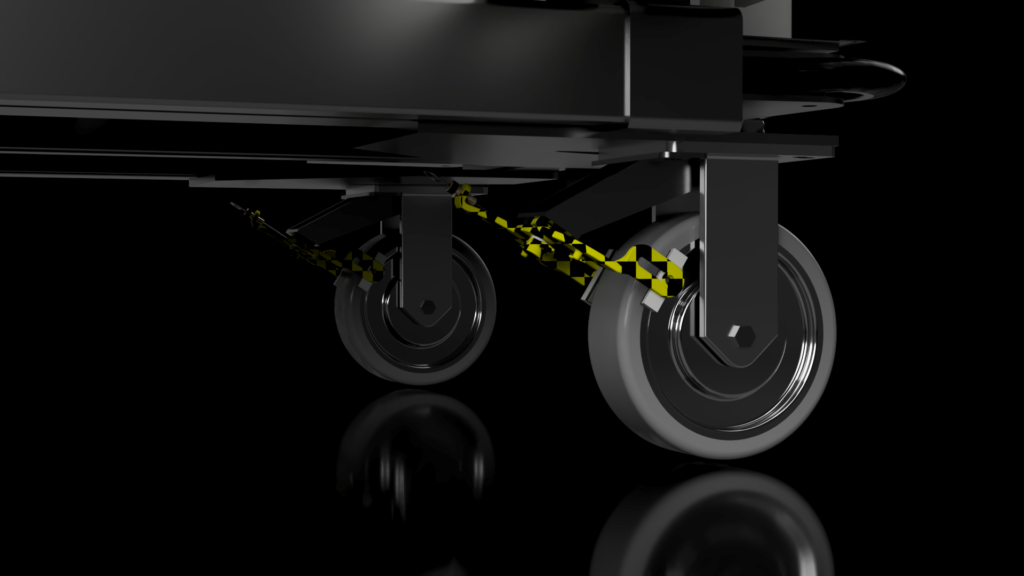

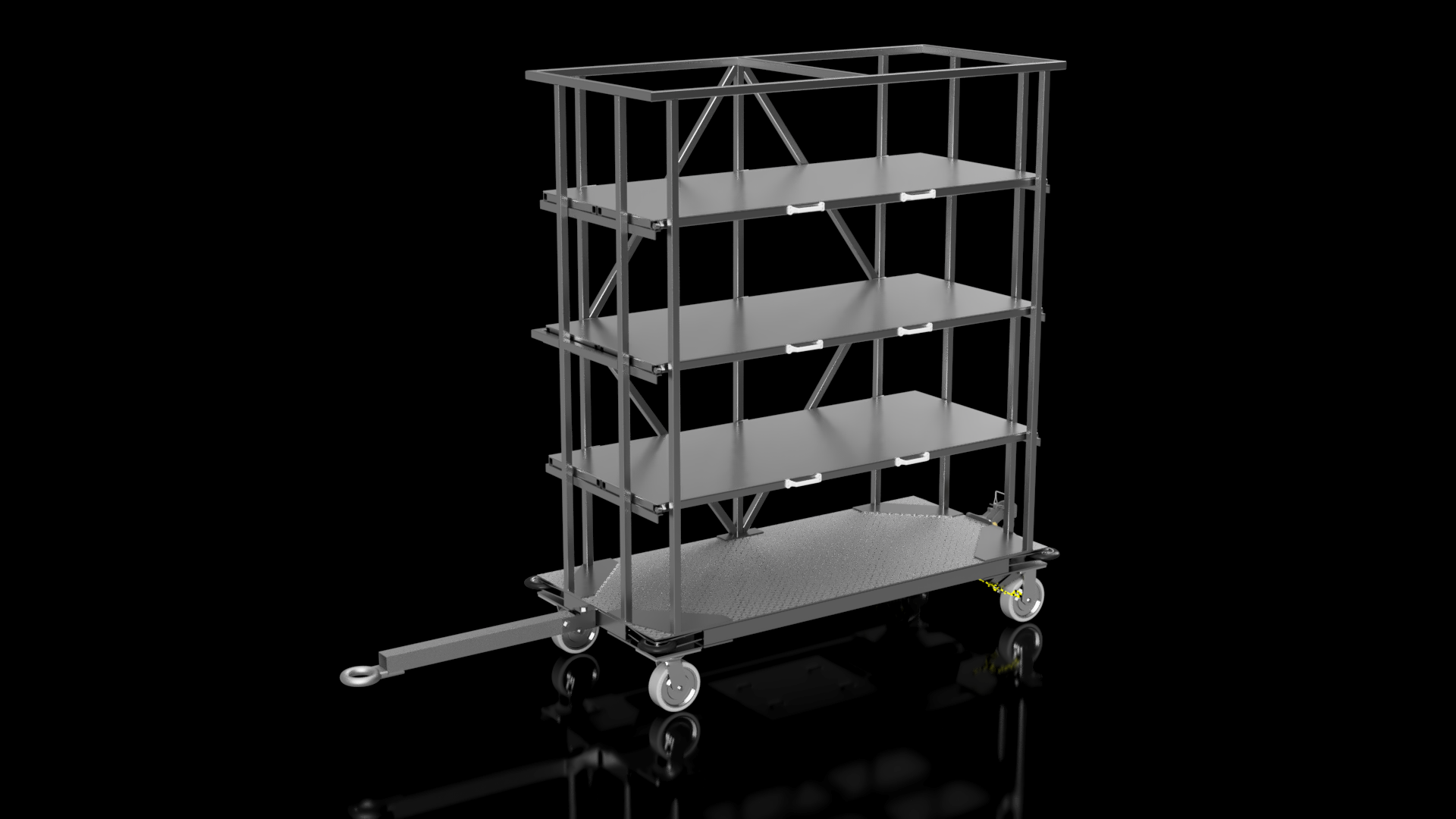

A pair of rigid casters on one side of the cart and a matching pair of swivel casters on the opposite side of the cart allow us to optimize cart maneuverability and minimize operator exertion. The heavy duty, 6″ dia. thermoplastic rubber (TPR) casters, equipped with ball bearings ($9 ea – rigid, $11 ea – swivel, CasterConnection), enable easy human push/pull operation. These casters were selected due to the non-marking properties of TPR, usability on carpet, resistance to chemical wear, and prominence in industrial applications. Our rigid casters are fitted with a lockable bike V-brake system (~$8, Alibaba), controlled at the push/pull handles.

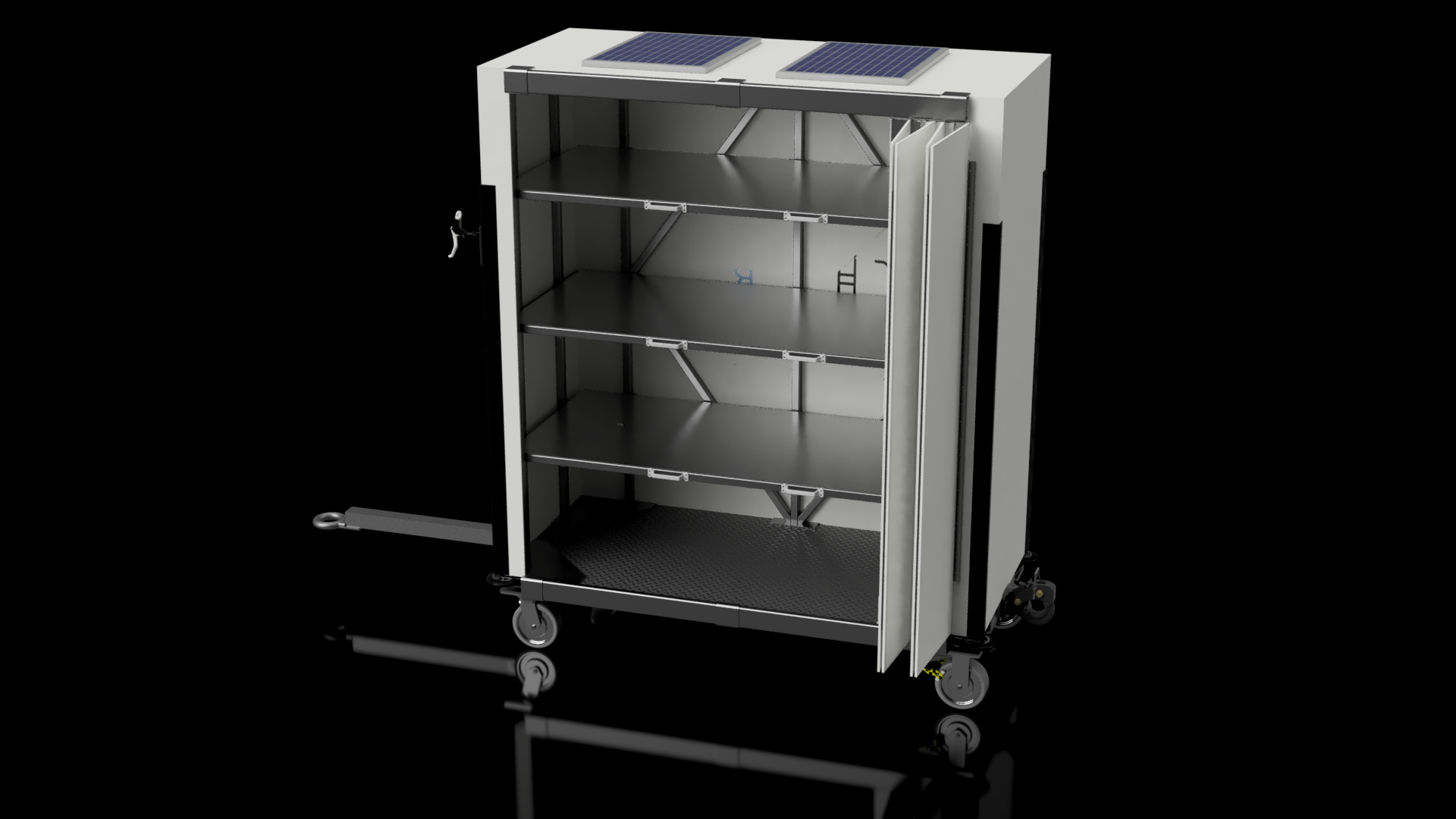

Cart Chassis

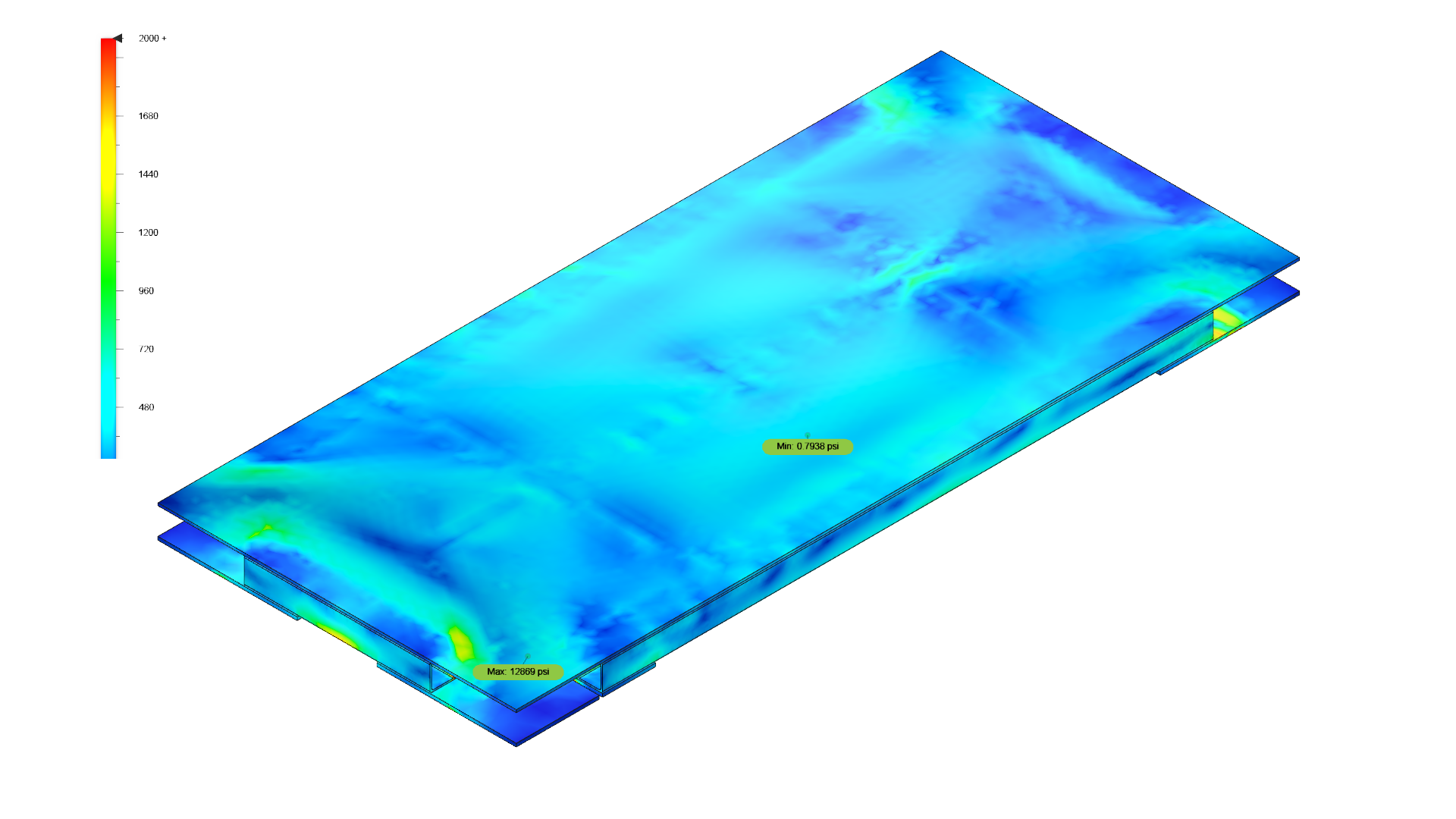

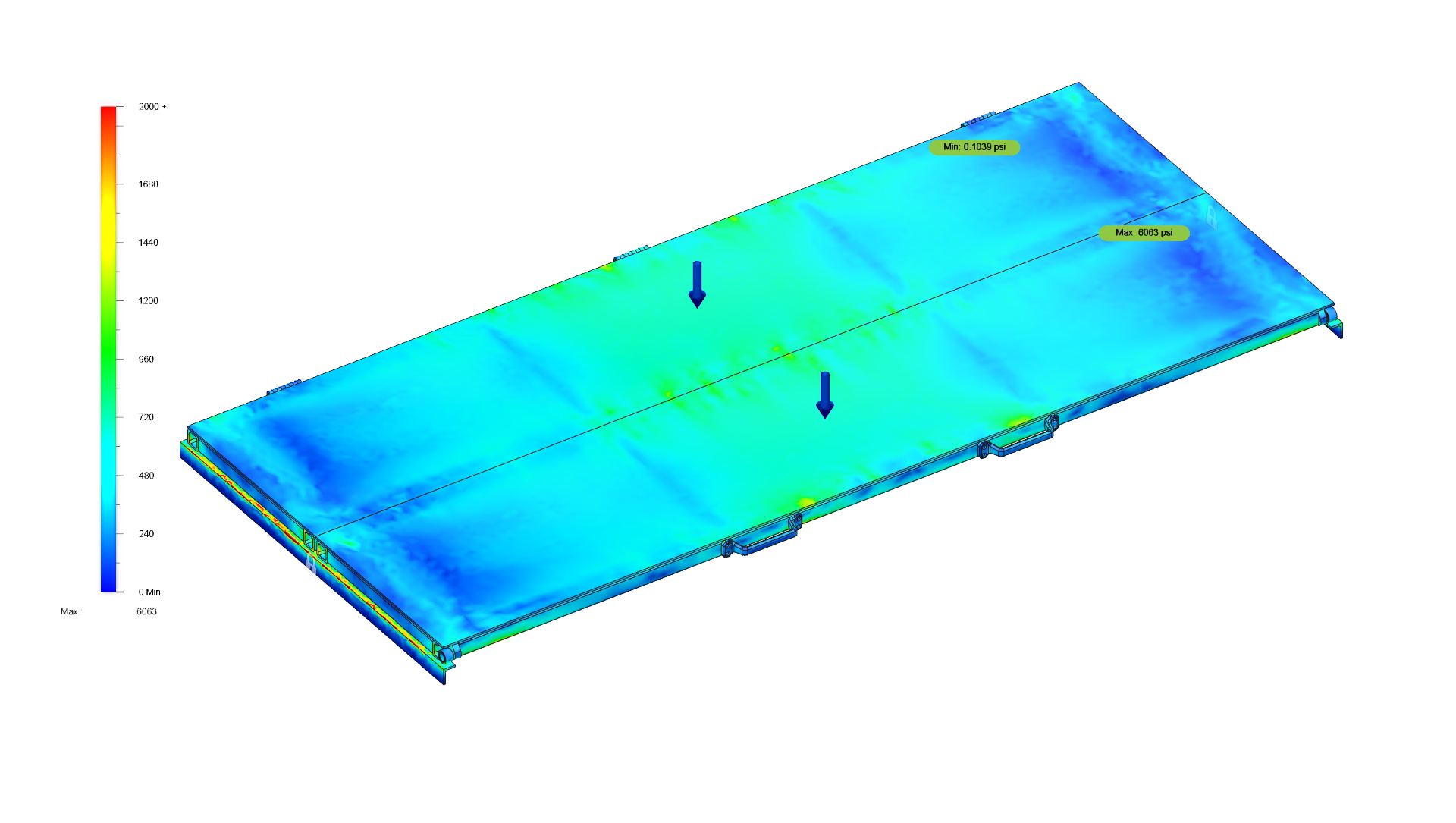

Chairiot’s cart chassis design is driven by a unique method of weight-sensing. The cart body is mounted entirely on rails, which are gusseted to each other. These rails, along with a unique gusset design, allow us to direct force and strain to optimum locations on the gussets. We mount strain gauges at these locations to measure cart capacity. This configuration, which places the wheels at the extreme ends of the AMTC, also reduces total vibration. To read more about Chairiot’s weight sensing capability, visit Weight Sensing.

Shelves

Our AMTC houses 3 58″ x 28″, double-jointed, non-interfering, protective-coated steel shelves, each with a 300 lb capacity and the ability to be folded down as 1, 2, or 3 shelves (based on loading needs). Each shelf features a joint along the back wall of the AMTC and a joint at the midsection of the shelf, and full-length supports to prevent sagging. The shelves, stowed at the back of the cart, are folded by the operator via handles and rest on brackets mounted along the sides of the cart.

Tow Bar

Our AMTC features a steel front-mounted 26″, ringed tow bar to easily couple to standard airport tuggers or other AMTCs. The tow bar is fixed to the AMTC via steel-fabricated dual-axis hinge, allowing for drop-down/stow motion and increasing towing maneuverability. The rear of the AMTC features a steel pin hitch that can support towing up to an 7 cart train (or 7700 lbs). This pin hitch has a spring loaded drop-down fork to lock over the tow ring and prevent unintended decoupling.

Door

Security, space, and ergonomic concerns drive the door design scheme. An accordion-style open and close configuration saves space and is simpler to implement than a telescoping or full-sliding door. Vertical rails on the top and bottom of the cart allow the door to move smoothly and with little operator exertion. Finally, the door carriage connected to the rail also locks into the wall; the lock can be opened manually, remotely, and via RFID card thanks to a small, wirelessly-connected servo installed in the wall.

Chairiot Heavy has 4 panels (dual carriage) to minimize the outside dimensions of the cart, while Chairiot has 2 panels (single carriage).

Communication

Chairiot’s CPU is equipped with a Cypress CYW43455 WiFi and Bluetooth chip, connected to a Proant PCB antenna. The WiFi is dual-band (supporting both 2.4GHz and 5GHz bands) and gives Chairiot true IoT capability. WiFi here is the obvious choice, because in-building WiFi coverage is almost ubiquitous, and the amount of data that Chairiot needs to send will most likely be small and intermittent (with the exception of video feed from the AMTC’s camera). Still, the chip is capable of 46Mbps upload/download on the 2.4GHz band and 102Mbps upload/download on the 5GHz band. The range is moderate and can be extended with a larger, external antenna.

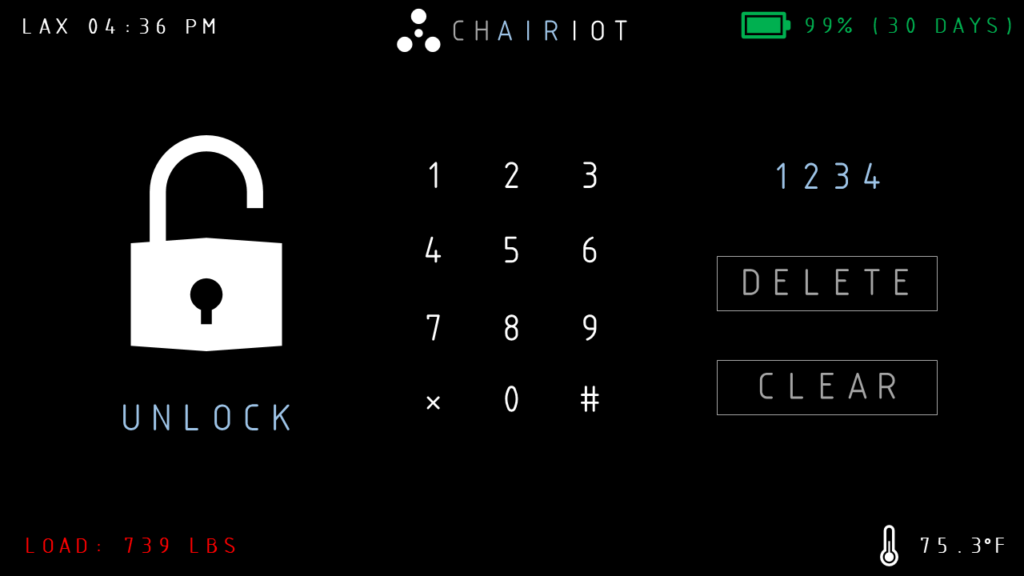

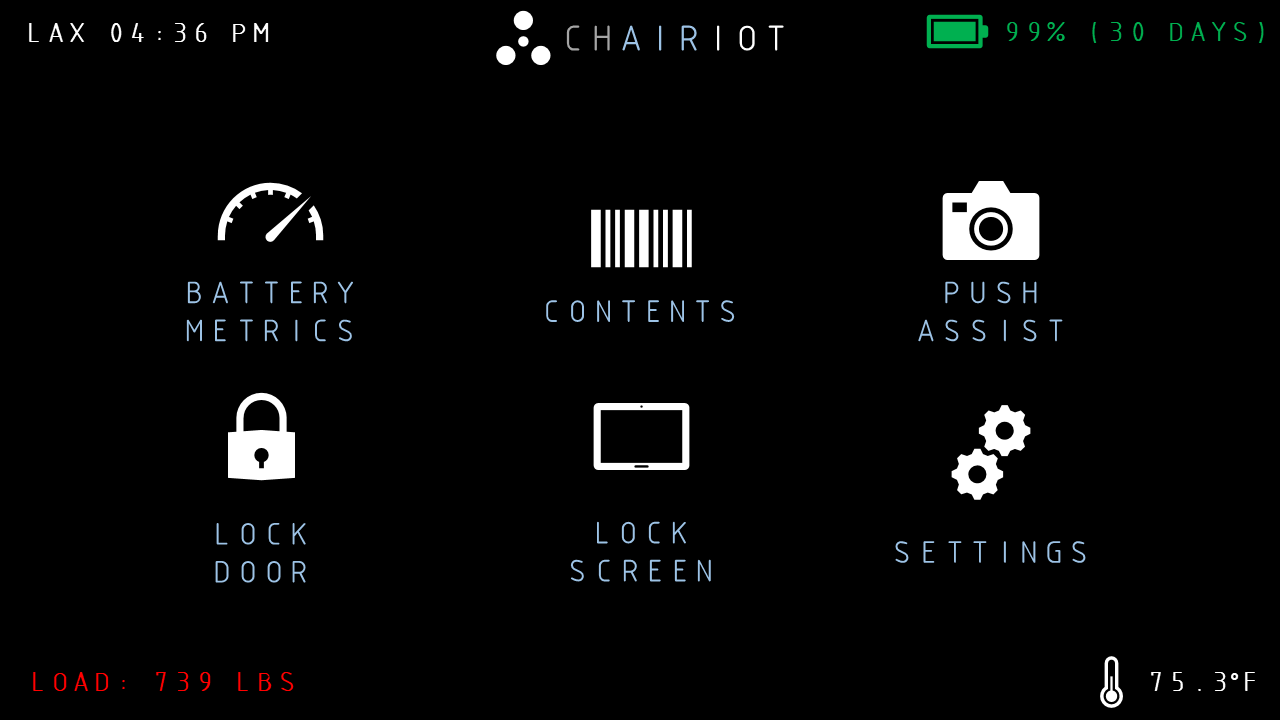

Programmable Label

Each AMTC features a front-mounted 8″ LCD industrial touchscreen “Programmable Label” ($50, Alibaba) directly integrated with the onboard, WiFi-equipped computer. Operators access the label’s functionalities by scanning an appropriate RFID badge or by entering a code. This customizable label displays the AMTC’s load (in lbs), temperature, battery metrics (time to full charge, time remaining, percent remaining, temperature), and serves as the back-up camera monitor when the AMTC is being pushed.

Safety

Chairiot Heavy, loaded at full capacity, has the potential to be dangerous if proper precautions are not taken. Chairiot takes a preventative approach to safety and attempts to mitigate troubles by scrutinizing likely causes for concern. For example, all the corners on the cart are covered by rubber safety bumpers. Chairiot’s wheels are lockable, and brakes are controlled by operator squeeze bars on the cart handles. On the opposite side, ultrasonic sensors notify the operator whether or not there is an obstruction – and a camera on the same wall gives the operator a full view of what’s in front of or behind him. This data is fed to the on-board display, which emits a sound when an object is detected. Finally, weight sensors detect when the cart is over capacity.

Materials and Durability

Chairiot is made of durable engineering materials with no compromises on price. The cart chassis, being the most likely component of the cart to fail, given its repeated load conditions, is constructed with 11-gauge structural steel, which has a yield strength of 40,000 PSI. The floor of the cart is mounted onto 2-inch square structural steel tubing. These specifications allow the cart to handle the necessary cart capacity of 750 lbs with a safety factor of at least 3.

The exterior body of the cart is made of high-density polyethylene (HDPE), which is strong enough to handle repeated stress from bags and other items slamming into the walls.